| |

Introduction to GS TerraElast

Flash Video Demonstration

Advantages & Benefits

- Cost-effective installation

and maintenance

- Safety

- Environmental compatibility

Technology

Product Characteristics:

- Drainage

- Fire Prevention

- Sound Absorption

- Key Characteristics (Summary)

Applications

- Road, sidewalk, and yard construction

- Sound insulation walls

- Additional applications

Download GS TerraElast

PDF Brochure

|

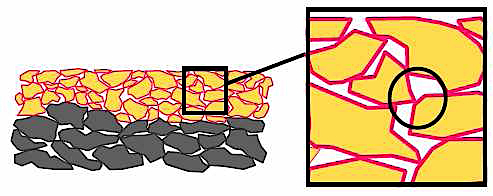

The GS TerraElast system coats each grain and bonds the stones into a stable,

sound-absorbent, and above all water-permeable composite.

The granulate is only bonded at the contact points.

This results in water-permeable “open”spaces

(proportion : approx. 40%).

This results in water-permeable “open”spaces

(proportion : approx. 40%).

Standard street cleaning used on conventional asphalt

roads prevents clogging of the pores.

On the other hand, ultra-quiet asphalt made of “leftover” used oil

compounds from the heavy oil industry is self-clogging, releasing its own

components when subjected to heat and pressure.

TerraElast is elastic, inherently stable, and does not leach; as a result, it is classified in water pollution class 0.

Installation Details

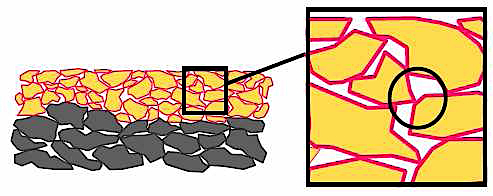

Sandwich Architecture:

Sandwich Architecture:

Road, sidewalk, and yard construction applications.

With GS TerraElast, only two layers are required:

1. Base Layer (Base Course) (10-25 cm)

2. Surface Course (2-4 cm)

=======> max. 29 cm total thickness

This 2 layer design offers material savings and improved effectiveness when compared to traditional asphalt applications which usually consist of 3 to 5 layers.

The base layer is made from coarse crushed stone (8/11 mm up to 22/33

mm depending on the requirements) is applied, graded, compacted,

and sprayed with a binding agent. The binding agent bonds the base

layer, creating a stable structure. The surface course is applied over

the base course.

The granulate for the surface course is evenly mixed with the binding

agent, applied over the base course in a viscous state, and then

smoothed and compacted with a roller.

The process uses conventional road construction mixers and surface preparation equipment.

Preliminary steps in the “asphalt mixer” are identical.

With a 25 cm base course and 4 cm surface course, the system is suitable for heavy traffic.

The surface is fully load-bearing after 24 hours, which results in cost reductions due to an efficient installation process.

Durability, Strength and Long-Term Performance

Long-term tests in Mannheim and Freiburg, Germany have shown:

Long-term tests in Mannheim and Freiburg, Germany have shown:

Water permeability - with a corresponding grain size (surface course 1- 3 mm), there is no significant reduction in seepage after 10 years.

The surface is resistant against acids, leaching, and solar radiation.

It is extremely pressure resistant and has a high tensile strength.

Faculty for the construction of state transportation routes, Prof.

Leykauf, Munich Technical University, research report 2362

dated 05/06/2007

“The tests that were conducted resulted in characteristic values

that indicate the load capacity of the structure under heavy

truck traffic (high axle weights) and equipment such as fork lifts

(high contact pressure while turning) is several times higher

compared to asphalt.”

Prof. Leykauf, Munich Technical University, research report 2385; 27/09/2007:

“In (wear tests under extreme conditions) ... with a tire contact pressure up to pm=0.8 N/mm², no surface deformation occurred (no lane grooves). ... The superstructure that was tested is highly resistant to deformation.”

GS TerraElast construction materials are more durable under heavy loads, remaining elastic and retaining their shape when exposed to heat.

Bending tensile strength up to 20 N/mm²

Pressure resistance up to 45 N/mm²

|